Two science teachers – one from Frontenac High School and one from Pittsburg High School – have been spending July learning from top researchers so that this fall in their classrooms, they can expand student knowledge and awareness. They didn’t have to travel far.

Anni Beasley, who teaches chemistry, physics, and physical science in Frontenac, and Sheila Sandford, who teaches physical science in Pittsburg, both are part of a paid summer internship program offered by the National Institute for Materials Advancement, or NIMA.

Based at Pittsburg State University, scientists at NIMA are working to refine rapid, safe, cost-effective, and renewable chemical processes to build a diversified manufacturing economy throughout the region.

They come from around the world to conduct their research, which they say ultimately serves industry and business, communities, academic institutions, and the global marketplace.

That research includes modifying readily available materials such as vegetable oils, proteins, starches, and cellulose to utilize in new and sustainable ways. It includes synthesizing and developing new polymers, plastics, and elastomers comparable to or better than conventional petroleum-based polymers. And it includes working with entrepreneurs and Fortune 500 companies to find and create innovative solutions.

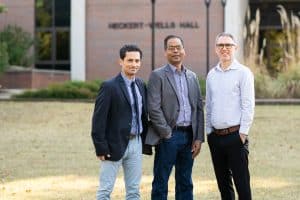

Scientist Mayank Chaudhary, center, shows a process to teachers Anni Beasley, left, and Sheila Sandford, right, at the National Institute for Materials Advancement based at Pittsburg State University.

During their internship, Beasley and Sandford have been able to observe many of these processes.

“I’m looking forward to bringing some real-life experiences back to my students, who might be asking when they are learning something in a classroom setting, ‘Why do I need to know this? How does it apply to the real world?’,” Beasley said.

Sandford recalled using state-of-the-art injection molding equipment at the nearby Kansas Technology Center.

“We learned the process of making something new out of something old,” she said. “We made golf tees out of ground-up plastics from recycled bottles, jugs, and the like. Along the way, we explored concepts like density in plastics.”

They also used a heat press to make small-scale items such as coasters out of ground-up larger items.

And, at nearby Heckert-Wells, home to Pitt State’s Chemistry Department, they learned the difference between bio-based and petroleum-based foams.

Overseeing their internship has been Professor Ram Gupta, who Stanford University named as one of the top 2 percent of scientists in the world.

“It’s been a big learning curve,” said Beasley of the experience. “It’s really interesting that this is happening in our little corner of the world.”